Our Services

Every Marylands garment is born from a rigorous process, built over time and refined with experience.

We follow every stage of the supply chain directly and responsibly, to ensure consistency between material, form, and style.

From design to shipping, everything happens in-house. Below are the services we offer.

Sample design and development

• Research and analysis of the initial concept

• Creative support and stylistic consultancy

• Visual interpretation of the brand

• Study of the fit and construction of the model

• Technical development of the sample collection

• Prototyping

• Consulting on trends, palettes, weights and yarns

• Adaptation of sketches for knitwear

• Meetings and reviews with designers and clients

• Management of technical and style changes

• Final validation of the sample item

Yarn selection and certified partners

• Research and supply of natural and mixed yarns

• Collaboration with certified and historic spinning mills

• Yarn sampling on request

• Consulting on the technical performance of materials

• Study of hand, weight and color rendering

• Proposal of alternatives based on budget and quantity

• Color-yarn matching based on the workmanship

• Monitoring yarn availability on the market

• Stock service yarns or dyed on request

• Traceability of the origin of materials

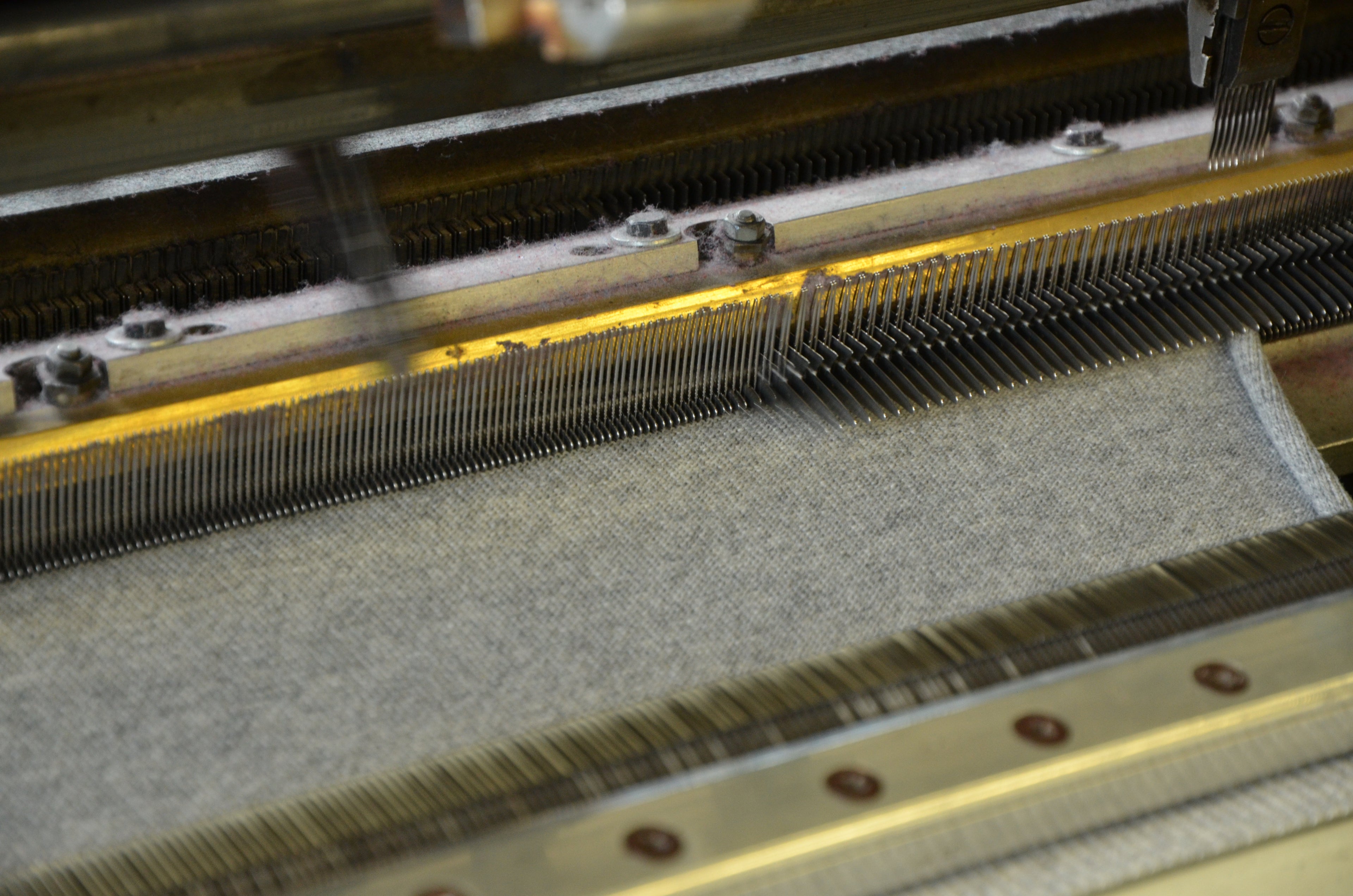

Knitting in all gauges

• Loom programming (Bentely Cotton, Stoll, Sheller, Shima Seiki)

• Wide availability of finenesses (3–18 days)

• Integration of basic, openwork, jacquard and inlay stitches

• Fully internal sewing machine

• Integration with historical straight frames

• Quality control at every step

• Sampling and prototyping

• Yarn/machine yield optimization

• Development of custom points

• Controlled mass production

Manual packaging and finishing

• Hand and machine assembly and sewing

• Manual or automatic clipping

• Joining panels and finishing of neck, shoulders, sides

• Riveting and any applications

• Check measurements and tightness of points

• Post-processing garment finishing

• Corrective interventions and defect elimination

• Personalization on request (labels, buttons, embroidery)

• Final quality control on each piece

• Treatment of delicate or complex garments

Checking, washing and ironing the garment

• Hand wash, machine wash, with or without fabric softeners

• Calibrated water and dry treatments

• Stabilization of measures

• Color rendering control after washing

• Hand or press ironing

• Stability and fit control of the finished garment

• Post-wash treatments available upon request

• Pre-packaging check

Finishing, packaging and shipping

• Manual envelope

• Logo and brand tag labeling

• Single or set packaging

• Customized packaging

•National and international shipments

• Tracking and logistics management

• White label service

Sample design and development.

Every project starts with a dialogue.

We support brands and designers from the early stages of the project, offering technical and creative support.

The creation of the sample collection is born from a concrete exchange, in which we make our experience and our production capacity available.

Each prototype is the result of a shared, precise, and tailor-made process, meeting the client's needs and enhancing every detail.

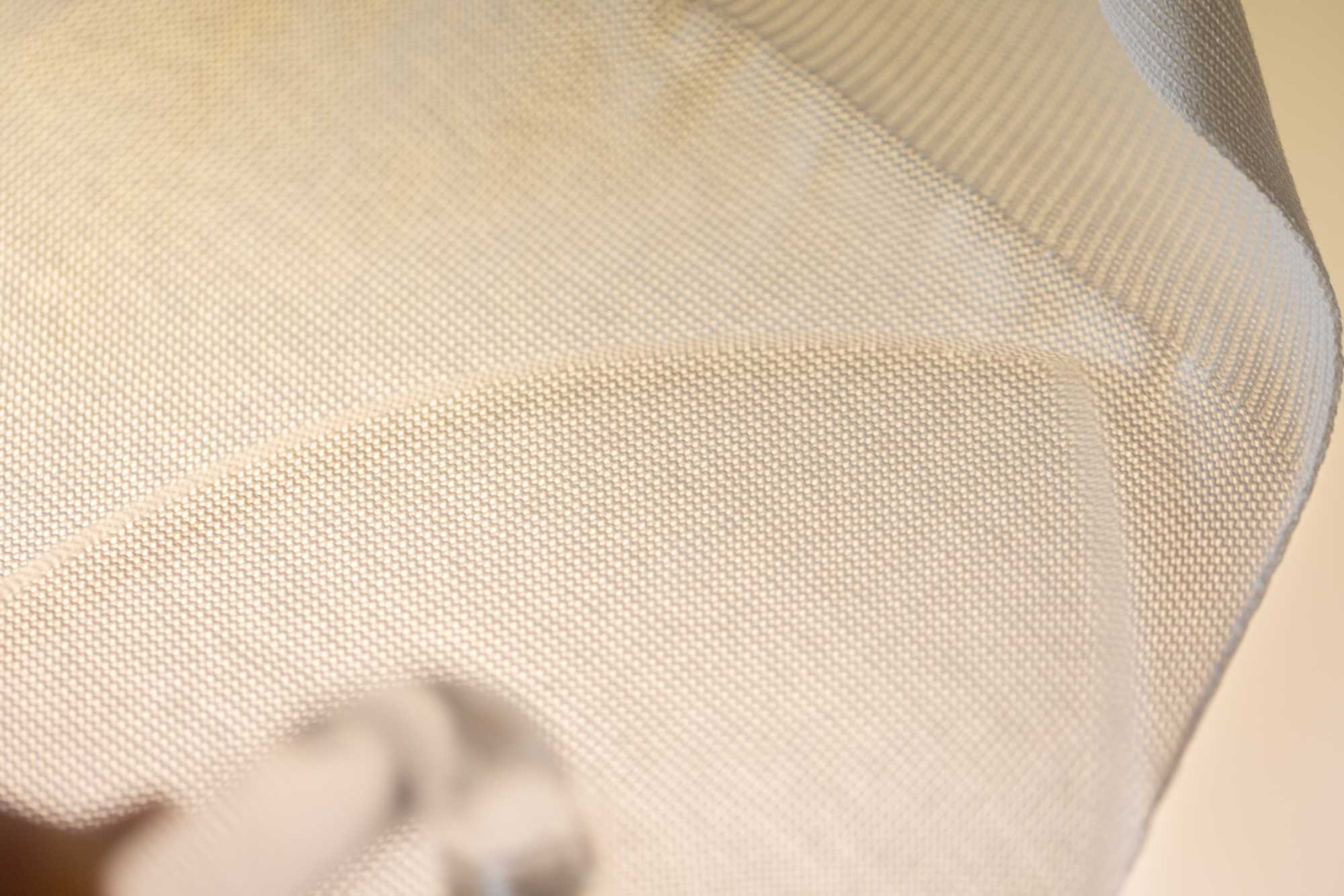

Selection of certified spinning mills and partners.

Choosing well is the first gesture of quality.

We work with the most renowned spinning mills in the national and international markets, with whom we have built long-term relationships.

Cashmere, silk, cotton, merino wool, lamb wool, and many other fine fibers; we always choose materials that meet the highest standards of quality, consistency, and stability, evaluating every technical and aesthetic aspect.

We develop custom yarns upon request, based on the characteristics needed for each project. The selection is always precise and thoughtful, because the material is an integral part of the final result.

Knitting in all gauges.

Innovation and tradition.

Knitting is a central point in the production process.

We have a large and flexible machine park, covering all gauges from 3 to 18 gauge, which allows us to tackle different projects, both simple and complex, with precision and consistency.

Manual packaging and finishing.

Details make the difference.

We package each garment following established methods and high standards.

The manual finishing ensures uniformity and cleanliness, with a quality that can be perceived in every aspect of the garment.

Our work is precise, silent, and effortless. Adhering to the rules of the trade is an act of consistency for us: everything is designed to be well done and to last.

Checking, washing and ironing of the garment.

Each garment takes its final shape with the right treatment.

Washing serves to stabilize the garment, fix its shape and define the handle.

Each yarn requires specific treatment, calibrated for its construction and structure.

Even ironing follows precise rules, to maintain the shape and enhance the volumes of the garment

Finishing, packaging and shipping.

Precision and care right up to the moment of delivery.

Each garment is carefully monitored in-house down to the last detail: folding, labeling, and quality control are all performed in-house to ensure consistency and precision. Logistics are managed with punctuality and traceability, ensuring reliable deliveries on time.

Contacts

At Maryland's, we're always looking for new talent and collaborators to join our team.

Contact us based on your needs in the dedicated sections.