THE FACTORY

TRADITION AND INNOVATION SINCE 1958

Our production facility integrates historic machinery and latest-generation technologies, ensuring versatility and control over all phases of the process.

TRADITION AND INNOVATION SINCE 1958

Our production facility integrates historic machinery and latest-generation technologies, ensuring versatility and control over all phases of the process.

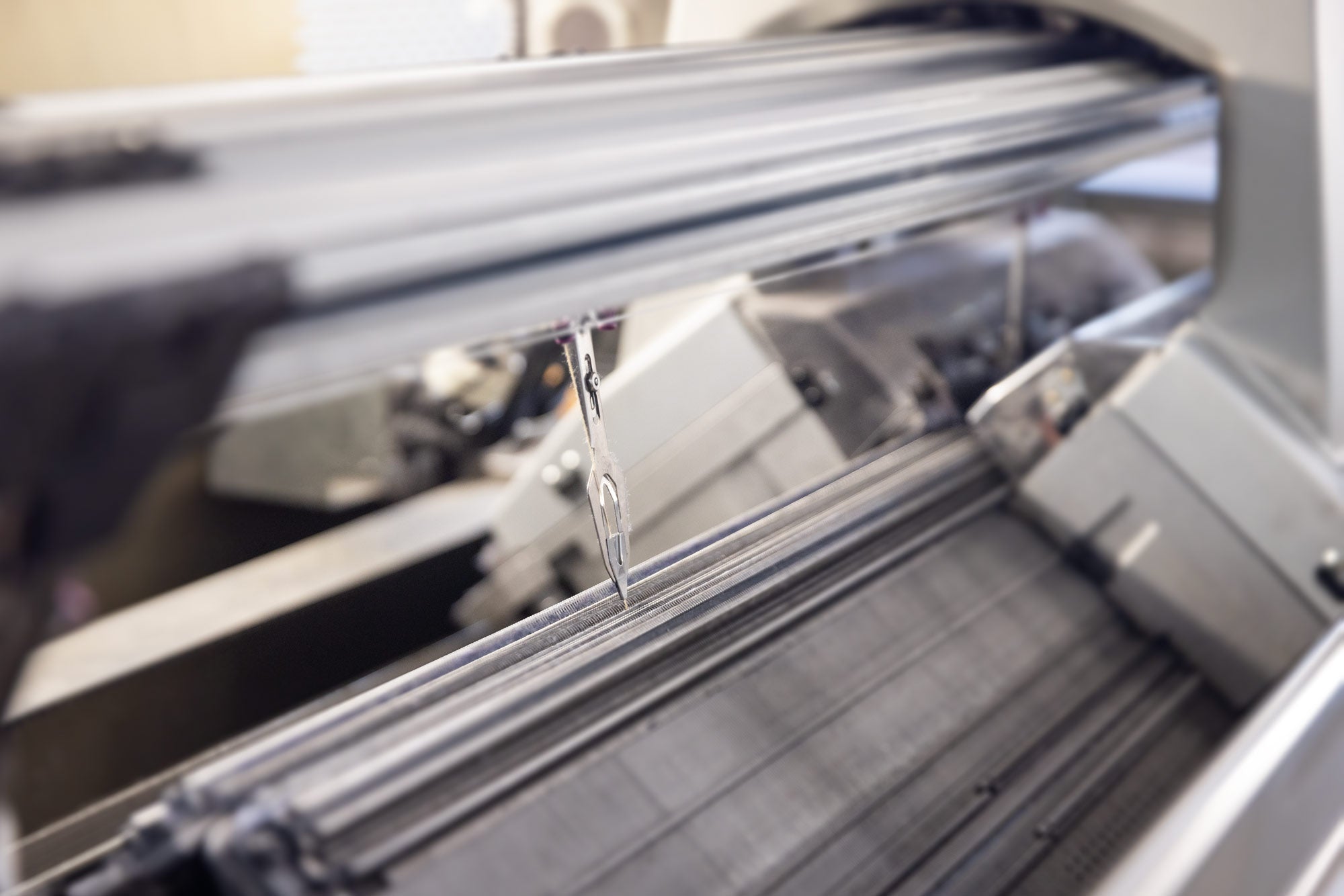

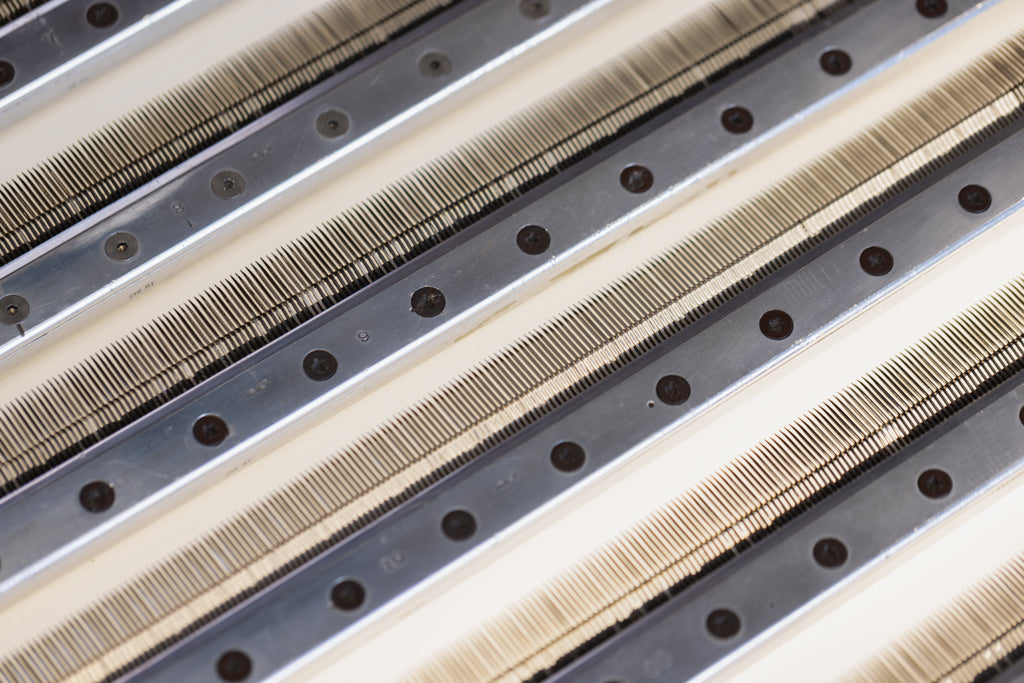

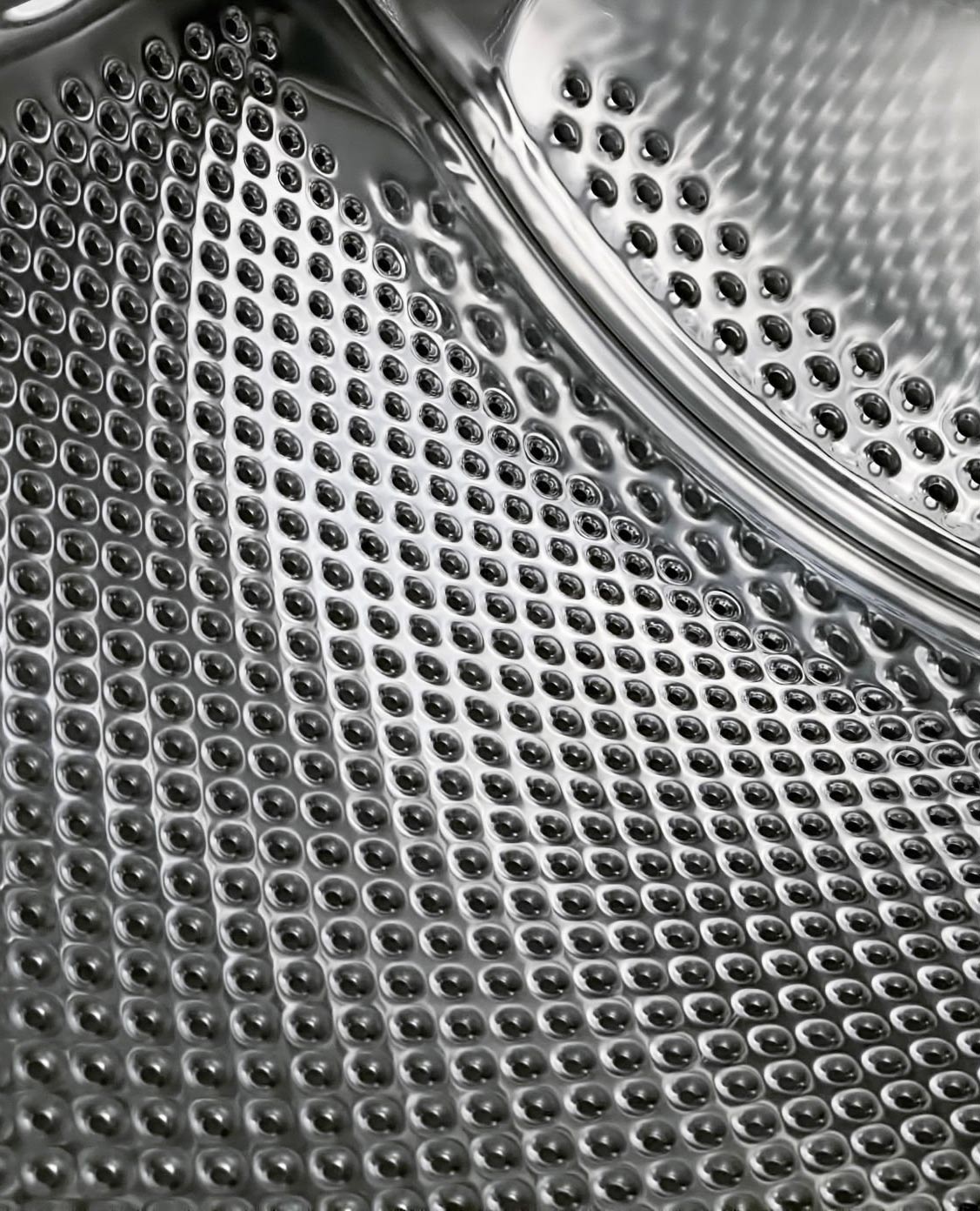

Knitting machines: between tradition and innovation

Our workshop combines historic machinery with cutting-edge technology. Bentley Cotton, Stoll, Sheller, and Shima machines allow us to cover all gauges, offering a wide variety of production solutions. A vibrant collection of textile mechanics, allowing us to interpret each project with the right tools, always striving for quality.

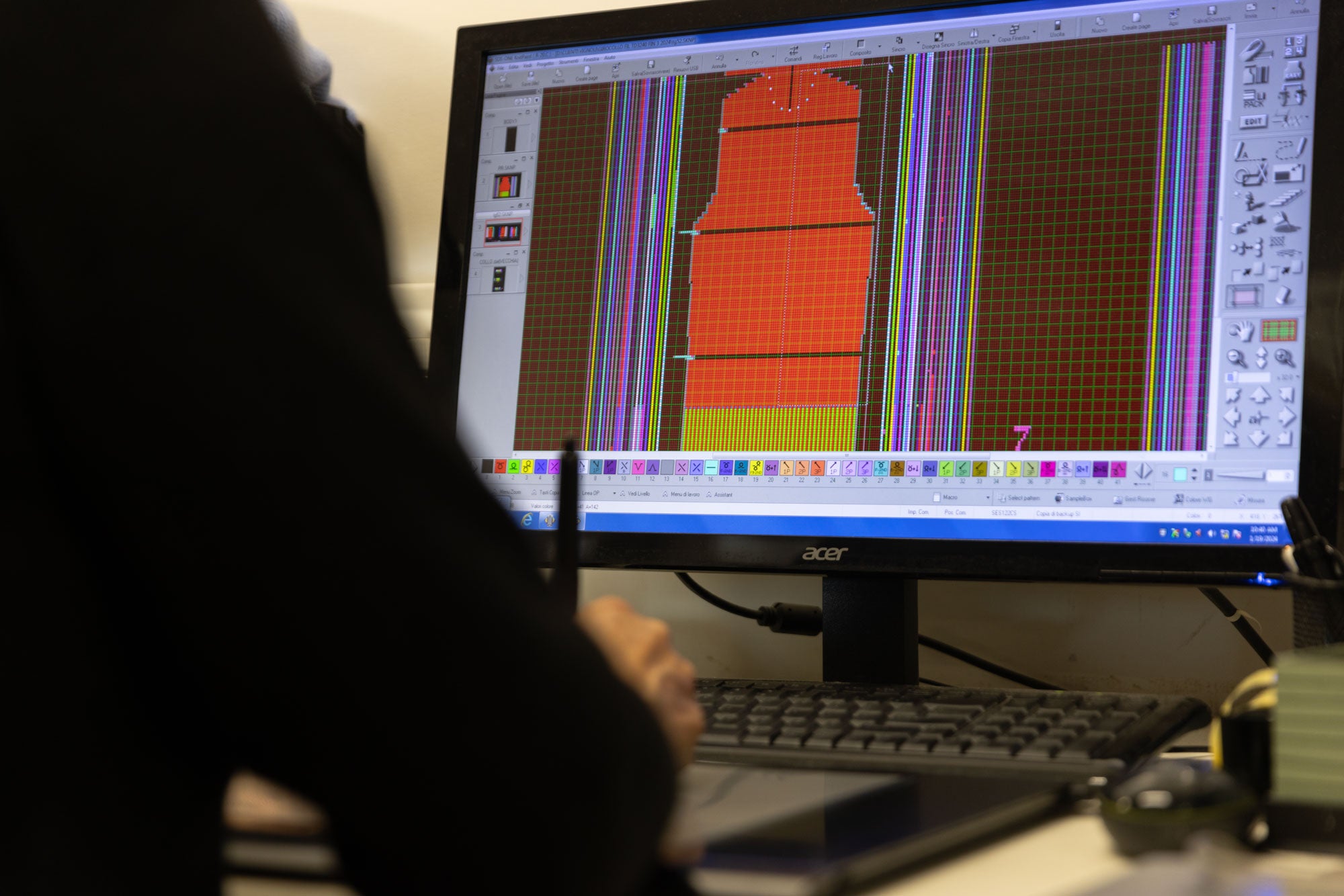

In-house design phase

An in-house team of designers and programmers oversees the development of sample collections, translating ideas into form and structure. From design interpretation to technical development, each phase is managed internally to ensure consistency, control, and timely delivery. We bring even the most complex requests to life with method and creativity.

Artisan packaging

Each piece is crafted with meticulous sartorial care. The expert hands of our artisans translate every stitch into a precise gesture, crafting shapes, volumes, and finishes with the care that comes from experience. This is where technique meets the sensitivity of the craft.

Inspection, washing, ironing and finishing

Each piece is inspected, finished, washed, and ironed in-house. We use only carefully selected, high-quality yarns and raw materials. Controlling every step of the process allows us to guarantee reliable, long-lasting results that are faithful to the original design.

For an excellent result

From the idea to the finished garment, every step begins and develops within our laboratory. A vertical supply chain, expertise built over sixty years of experience, and unwavering attention to detail allow us to offer a solid, consistent final product that lives up to the highest expectations.